Automatic Paper Corrugated Paperboard Bursting Strength Test Machine Burst Lab Testing Instrument

Description

Basic Info.

| Model NO. | XD-A01 |

| Accuracy Grade | 0.5 |

| Load Way | Electronic Load |

| Loading Method | Dynamic Load |

| Display | Digital |

| Control | Computer Control |

| Weight | 0-100Kg |

| Power Source | AC220V |

| Oil Cylinder Position | Under |

| Material of The Ring | Stainless Steel SUS304 |

| Motor | Anti-Vibration Motor 1/4 HP |

| Indicating Method | Digital |

| Sensing Method | Pressure Transmitter |

| Speed of Compression | High Pressure 170± 10ml/Min |

| Specimen Clamping Force | >690kpa |

| Pressure Range | 250~5600kpa |

| Transport Package | Standard Export Wood Package |

| Specification | Customizable |

| Trademark | Astrand |

| Origin | China |

| HS Code | 9024800000 |

| Production Capacity | 5000pieces |

Product Description

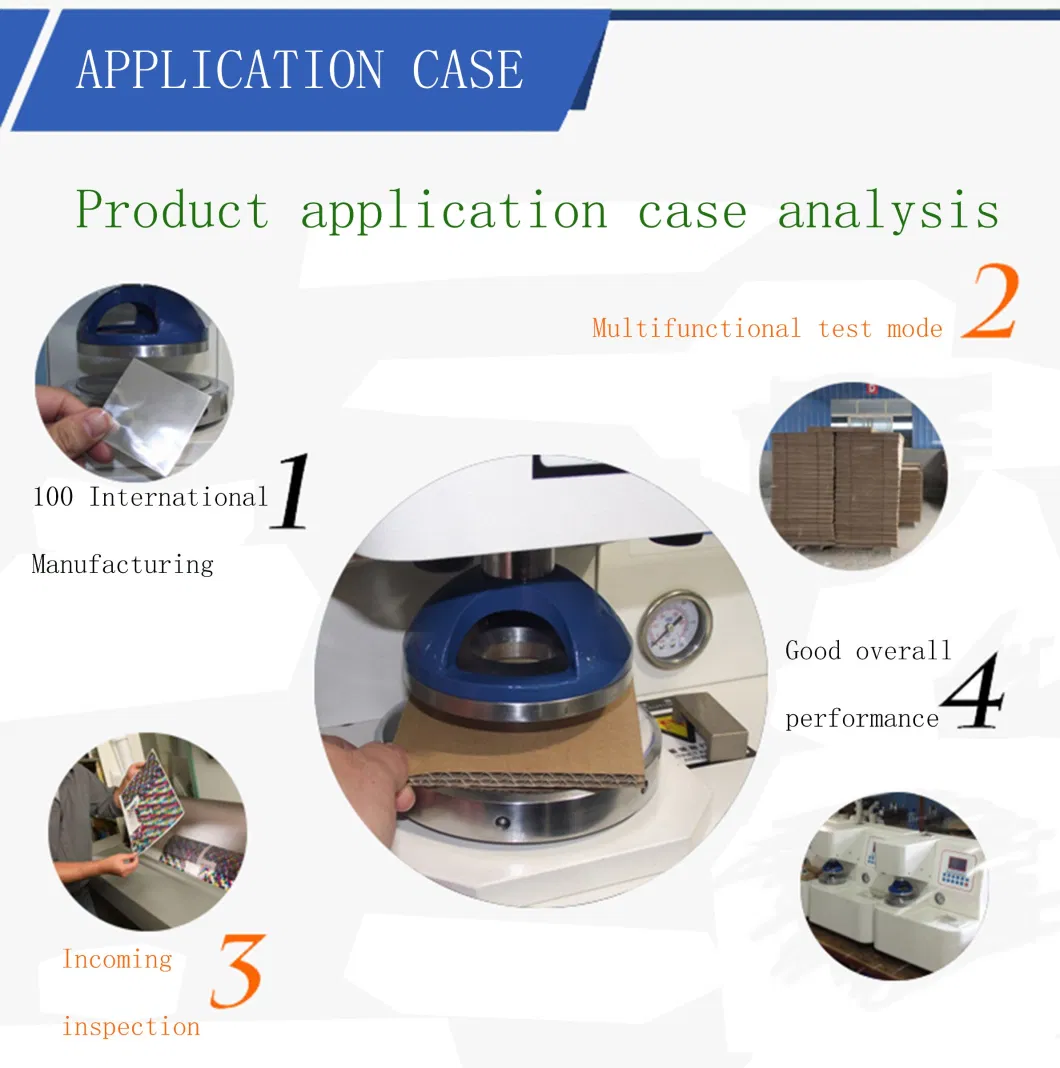

Automatic Paper Corrugated Paperboard Bursting Strength Test Machine Burst TesterProduct DescriptionApplication:The machine is used to detect the burst strength and burst index of paper and cardboard. It is to detect the ability of the carton to protect the product during handling, loading and unloading, impact, tearing and extrusion during the circulation process. It is the comprehensive performance of the carton. one of the evaluation methods. Suitable for box board, kraft paper, cardboard, corrugated paper, gray board paper, etc. It is more suitable for carton manufacturers, carton users, scientific research institutions and so on.Standards: GB/T454, QB/T 1057, ISO 2758

Product Parameters| High-end | Standard |

High-end:

| Measuring range | 70~1600kpa (paper), 150~5600kpa (corrugated cardboard) |

| Power Resolution | 1/100000 |

| Data analysis sampling | sampling frequency 400 times/second |

| Force accuracy | ±0.1% of indicated value (20~100%FS) |

| Accuracy | ≤±0.5% |

| Resolution | 0.01kpa |

| Deformation error | ≤1mm |

| Concentricity of upper and lower discs | ≤0.25mm |

| Film convex plate pressure | (9±0.2)mm/(30±5)kPa |

| Oil delivery speed | 95±5ml/min (paper), 175±5ml/min (corrugated cardboard) |

| Platen Diameter | Diameter of upper plate: 30.5±0.1mm; diameter of lower plate: 33.1±0.1mm (paper)Diameter of upper plate: 31.5±0.1mm; diameter of lower plate: 31.5±0.1mm (corrugated cardboard) |

| Human-machine interface | 7in touch screen |

| Test control | with delay pressurization control, with decompression delay control |

| Clamping force | 100kpa~1200kpa (adjustable), with voltage stabilization function to ensure stable holding force |

| Oil cup system | high-strength and high-pressure oil circuit sealing system, with double sealing knob, 25mm high-pressure 30 stainless steel oil pipe |

| Circuit board chip protection | comes with a water vapor filter device to protect the stability of the circuit device |

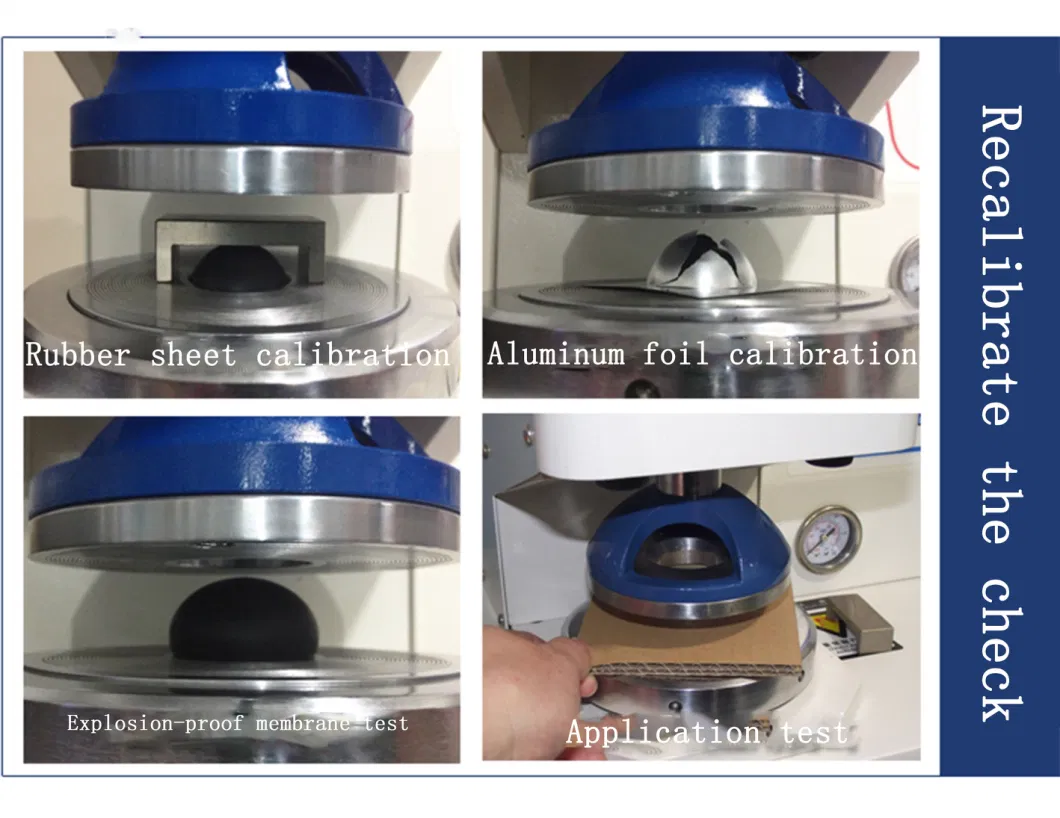

| Calibration system | Self-contained calibration system, self-contained manual pressurization and decompression control system |

| Test head material | the cylinder part, the upper clamping part and the lower clamping part are all 304 stainless steel |

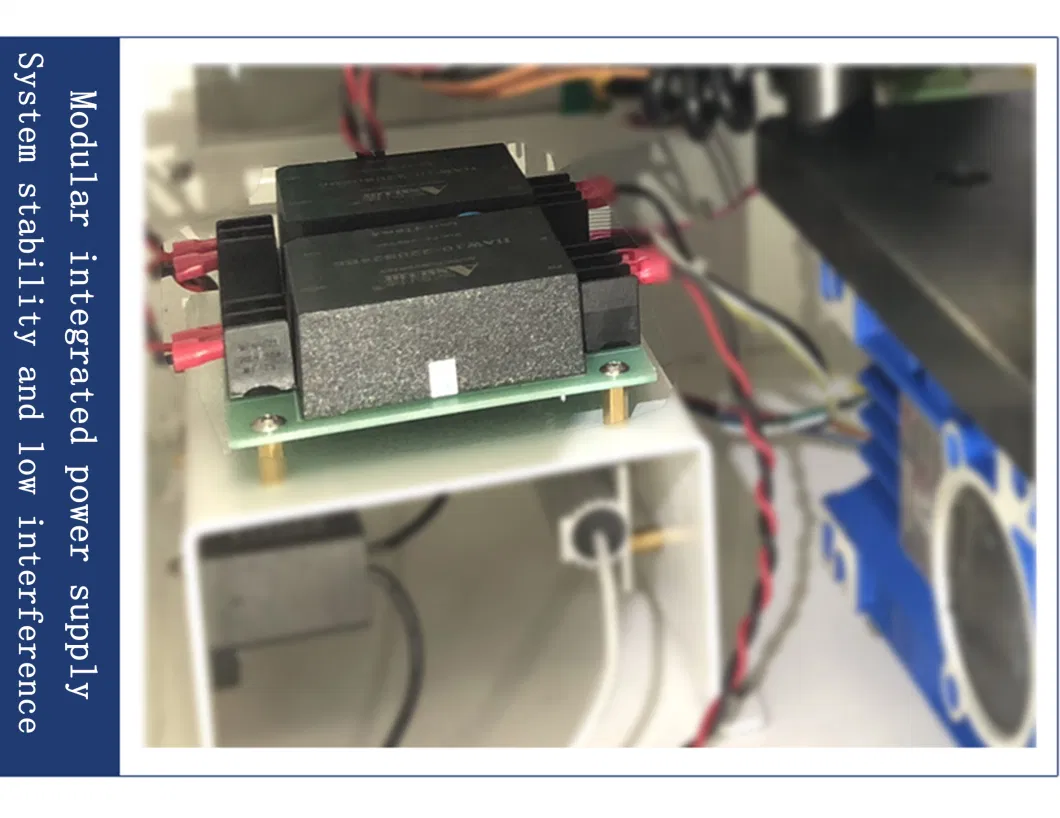

| Safety device | with safety cover, with power supply anti-interference protection module |

| Unit conversion | Kg/cm2, kpa, lbf/in2 |

| Printout | Modular all-in-one thermal printer |

| Weight | 55KG |

Standard:

| Measuring range | 150~5600kpa (cardboard) 50~1400kpa (paper) |

| Accuracy | ≤±0.5% |

| Resolution | 0.01kpa |

| Deformation error | ≤1mm |

| Concentricity of upper and lower discs | ≤0.25mm |

| The pressure of the film convex plate | 10mm, (170~220)kPa; 18mm, (250~350)kPa (cardboard)(9±0.2)mm/(30±5)kPa (paper) |

| Oil delivery speed | 175±5ml/min (cardboard); 95±5ml/min (paper) |

| Pressure outer diameter | 35mm±1mm |

| Work displacement | 53mm±2mm |

| Platen diameter | Upper plate diameter: (31.5±0.5)mm; Lower plate diameter: (31.5±0.5)mm |

| Deformation monitoring | chord length 41mm, three-dimensional semicircle full-window observation window |

| Test control | with delay pressurization control, with decompression delay control |

| Drive structure | all-steel chain drive to prevent deviation of compression and improve detection stability and service life |

| Oil cup system | high-strength and high-pressure oil circuit sealing system, with double sealing knob, 25mm high-pressure 30 stainless steel oil pipe |

| Circuit board chip protection | comes with a water vapor filter device to protect the stability of the circuit device |

| Power supply block device | anti-interference, prevent electromagnetic field instability, ensure the accuracy and reliability of test data |

| Calibration system | Self-contained calibration system, self-contained manual pressurization and decompression control system |

| Test head material | the cylinder part, the upper clamping part and the lower clamping part are all 304 stainless steel |

| Clamping force | greater than 690kpa (adjustable) |

| Human-machine interface | 7in touch screen display, easy to operate |

| Unit conversion | Kg/cm2, kpa, lbf/in2 |

| Printout | Modular all-in-one thermal printer |

| Dimensions | 400mm×400mm×500mm |

| Weight | 50KG |

Dongguan Astrand Electronic Technology Co., Ltd, with its own brand--ASTRAND, has been dedicating in providing professional testing equipment with top quality since its establishment in 2007. It owns sophisticated and advanced technology in producing Fabric Textile machine, Shoes/Footwear Testing Equipment, Paper and Paperboard Testing Equipment, Environmental test chamber, Universal Tensile Strength Testing Equipment and so on. Products made by ASTRAND reach international standards: ISO, ASTM, DIN, EN, GB, BS, JIS, TAPPI, AATCC. Also they are widely used in different area: R&D Institutions, Quality inspection institutions, universities,electronics, communications, instrumentation, automobile, aviation, etc.

Prev: Hospital Machine Device Medical Lab Instrument Electrolyte (XI

Next: Laboratory Equipment Ista Carton Box Package Simulation Vibration Testing Machine/Instrument

Our Contact